> The Problem

Ringette is an ice sport similar to hockey, but players control a rubber ring with a straight stick rather than a puck and blade. Our client for the project was the former owner of DOM Sports, a top ringette ring retailer. Realizing that the ringette ring hadn’t seen any meaningful change in decades, he wanted a new ring with improved performance (e.g, faster speed and control) while staying within official dimensions, mass, and rubber material rules. I was chosen as the team lead for this project and along with a group of 5 other University of Toronto students, we were tasked with redesigning the Ringette ring.

Ringette players

> The Design Process

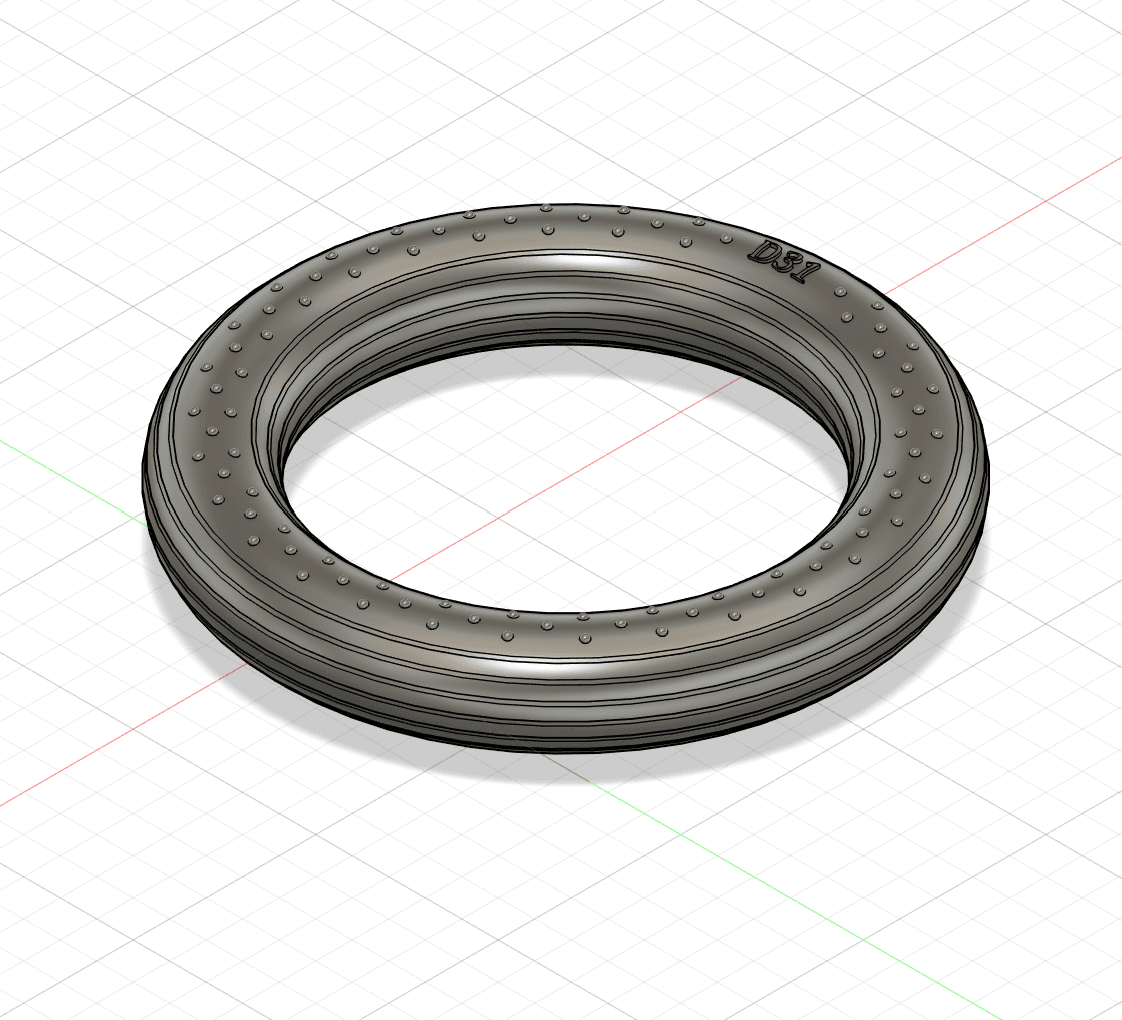

We started broad and generated 50+ full concepts using a mix of free brainstorming (open group idea generation) and structured brainstorming (quiet solo idea writing to reduce groupthink). We organized idea families with a morph chart which is a simple grid listing key functions (e.g., surface texture, edge profile, mass distribution) against alternative ways to achieve each function, so we could systematically combine promising features. Once we had enough ideas, we began the process of trimming down to only our best designs. We first filtered out anything violating size/material rules, then used a voting system to surface favorites. Then, I personally 3D modelled our top 3 designs in Fusion 360 so that we could visualize each concept. For these designs we compared options with a weighted decision matrix (a multi-objective scorecard where high-importance criteria like friction and control receive higher weights), so the selection reflected evidence, not gut feel.

> The Proposed Design

The concept we selected added rounded surface bumps to reduce the real area of contact against the ice (lowering sliding friction), and introduced subtle inner ridges to improve stick control. We also tuned the mass toward the outer rim of the ring for steadier, more predictable motion, and ensured the overall geometry stays within official dimensions and material requirements, preserving legality.

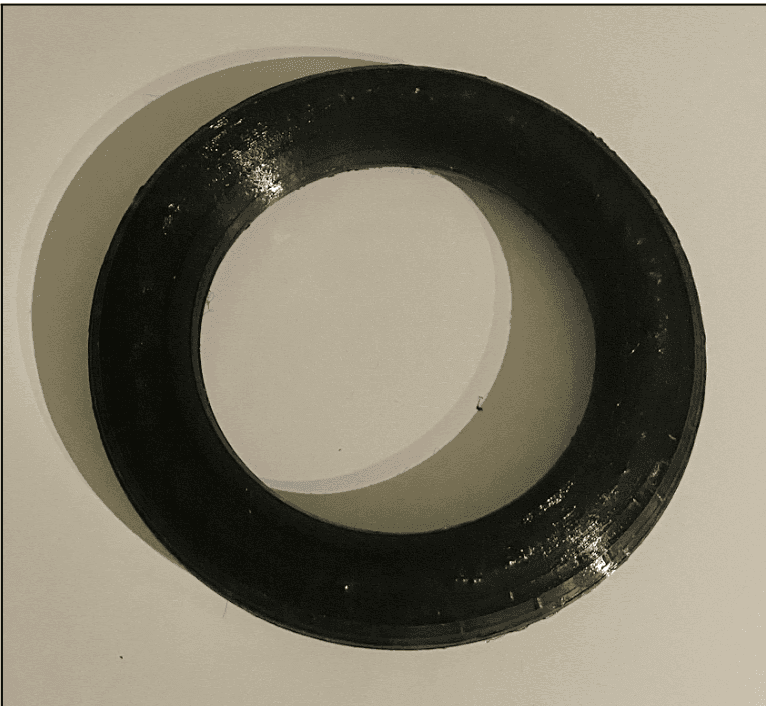

3D print of the proposed design

> Testing and Validation

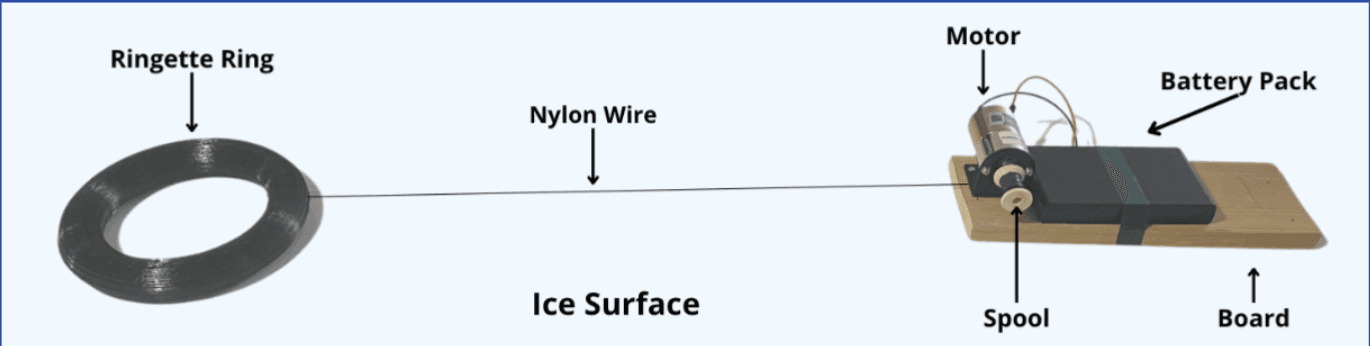

To compare fairly against the original ring, I 3D-printed a prototype of our geometry in TPU (a rubber-like material) and also printed a control with the same material but original shape, isolating geometry as the variable. On ice, we applied a constant pull using a motor, filmed motion, and extracted speed/acceleration to infer the coefficient of kinetic friction which is a repeatable measure that correlates with how fast the ring will move on ice. Under identical pulls, the redesigned ring showed higher acceleration and slightly lower kinetic friction than the control, indicating more efficient sliding with maintained control. The position–time plot shows a steeper initial slope and higher plateau for our ring, consistent with the friction reduction targeted in the design. In short, the geometry changes produced a small but meaningful performance gain.

Position vs time plot of both rings

© Eshaan Marocha 2025